When it comes to machine tool or automation investments, metal fabricating companies all adopt the Missouri state slogan: “Show me!”

That’s easy to understand. Proof of a return on investment (ROI) always makes for easy decisions.

“At a time when North American manufacturers need to deliver high-quality products faster, while stressed with labor shortages, we are thrilled to announce the new APS Program, which can relieve some of their burden,” said Tony Landes, APS commercial manager.

Landes added that plenty of manufacturers had interest in learning about ways that they could optimize their metal finishing activities before the pandemic, but that interest has intensified in the face of rising labor costs. Proposed projects that once promised a five-year ROI based on labor costs before the COVID-19 crisis now show a two-year ROI because hourly wages have skyrocketed in some areas.

These types of process upgrades or automation investments grow more complicated when supply chain issues are factored in. Lead times for some robots, for example, can stretch out to as long as a year.

One of the goals of the APS Program, Landes said, is to show manufacturers that proposed process development improvements are indeed possible, giving them the confidence to move forward with their investments and get them to the point where they are reaping the rewards as soon as possible. The testing and quantitative data collection is done in Northborough, alleviating the need for the manufacturer to carve out time and find resources to do the same on its own shop floor, and the results are turned over to the manufacturer in a short time frame.

“Our lab is dedicated to these types of projects,” Landes said. “It’s an engineer’s playground.”

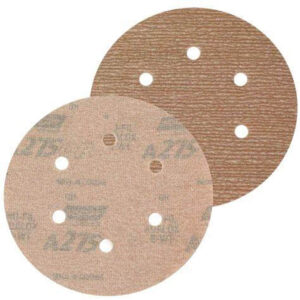

At the heart of the program is the APS Automation Cell, which is capable of testing all kinds of media-to-part (where the robot applies the abrasive to a fixtured workpiece) and part-to-media (where the robot moves the part to fixed abrasive machines) applications. The cell also can replicate wet and dry processing. The full range of abrasives, such as coated, nonwoven, thin wheel, bonded, and superabrasives, are accessible for testing.

A FANUC R2000iC 210-kg robot, which arrived in December 2021 and was up and running in February 2022, provides the automated movements needed for testing. The robot, which can detect the amount of force being applied and adjust accordingly, is equipped with an ATI tool changer capable of being paired with an end-of-arm gripper to hold parts being presented to the abrasive machine, or it also can be paired with a series of portable tools and spindles allowing the robot to hold abrasives that are then applied to workpieces.

The cell has two ACME finishing/grinding heads, both of which are variable speed. One machine, a stacked head, has a lower spindle that has a 40-HP motor, capable of driving large superabrasive, diamond, bonded, and cutoff wheels. The shaft also can drive any type of radial product up to 20 in. diam. The top head of the stacked unit is a 5-HP motor that can be used directly on a contact wheel or as the slack of the belt setup. The unit can run up to a 3-in.-wide belt of any type.

The second abrasive machine is a side-by-side finishing head that has a programmable pivot option for the base. This option creates a scenario where unusual-shaped components can be processed because the head can rotate at the same time that the armature robot is moving. The head also has the ability to run two belts simultaneously, using different grits, grains, and backings and various types of contact wheels in different types of setups. These contact wheels can be mounted on a pneumatic floating spindle to accommodate various pressure settings during the point of contact.

Landes noted that having variable-speed motors on the abrasive machines is very important to testing certain applications. It lets the lab show end users and system integrators the value of being able to vary speeds during processing.

On the media-to-part side of the lab, the robot has access to two motorized heads: a PushCorp. STC1015 10,000-RPM, 15-HP servo spindle and a PushCorp. STC0605 6,000-RPM, 5-HP servo spindle. The 15-HP motor is capable of holding various radial abrasive tools that require high levels of speed and power to achieve the specified results. The spindle is mounted on an AFD1240 compliance device so that the technician can control the amount of consistent force during the finishing process. The 5-HP motor is used for small and lighter abrasives. This spindle is mounted on an AFD310 active compliance device for a degree of force control and to prove that parts can be moved from manual to automatic applications while achieving similar results.

Landes said that the lab has completed about nine test cases as of mid-June, with another six underway. Simultaneously, the first formal presentations were being made to the company’s sales team, so the number of projects is expected to grow substantially in the latter part of the year.

Even though the APS Program is relatively new, Landes did share a couple of success stories. In one case, a manufacturer of recessed lighting fixtures was looking for a way to improve the process of buffing the interior of the light housings. The process involved fixed abrasive buff (FAB) wheels and the application of buffing compound. After working on the application in the lab, the APS team suggested projecting water onto the workpiece and then using a new Norton FAB buffing wheel, which had a silicon carbide abrasive uniformly dispersed and applied to both sides of the wheel’s cloth.

The manufacturer was invited to visit the lab and see the recommended process in action. Upon seeing that the end results were achieved without the need to apply, clean up, and dispose of large amounts of buffing compound, the company signed off on the new metal finishing equipment investments, which included mechanical adjustments to have water delivered to the workpiece during buffing.

“We’re more than comfortable having the customer in the lab watching over our shoulder. We’re not a closed lab,” Landes said.

In another instance, a manufacturer of railroad wheels was looking for an automated process to remove multiple defects in the wheels up to 0.125 in. deep, all within a 60- to 75-second process window. It also was hoping to use an abrasive belt that would survive over an entire eight-hour shift. The company was relying on manual grinders to do the same task with hand tools.

Landes said this is where the technicians had to get creative. Because they were unable to accommodate a complete railroad wheel in the lab, they requested a quarter of the wheel, which was a much better fit. The APS team also had to adjust the size of the abrasive to be used to reflect the confines of the lab.