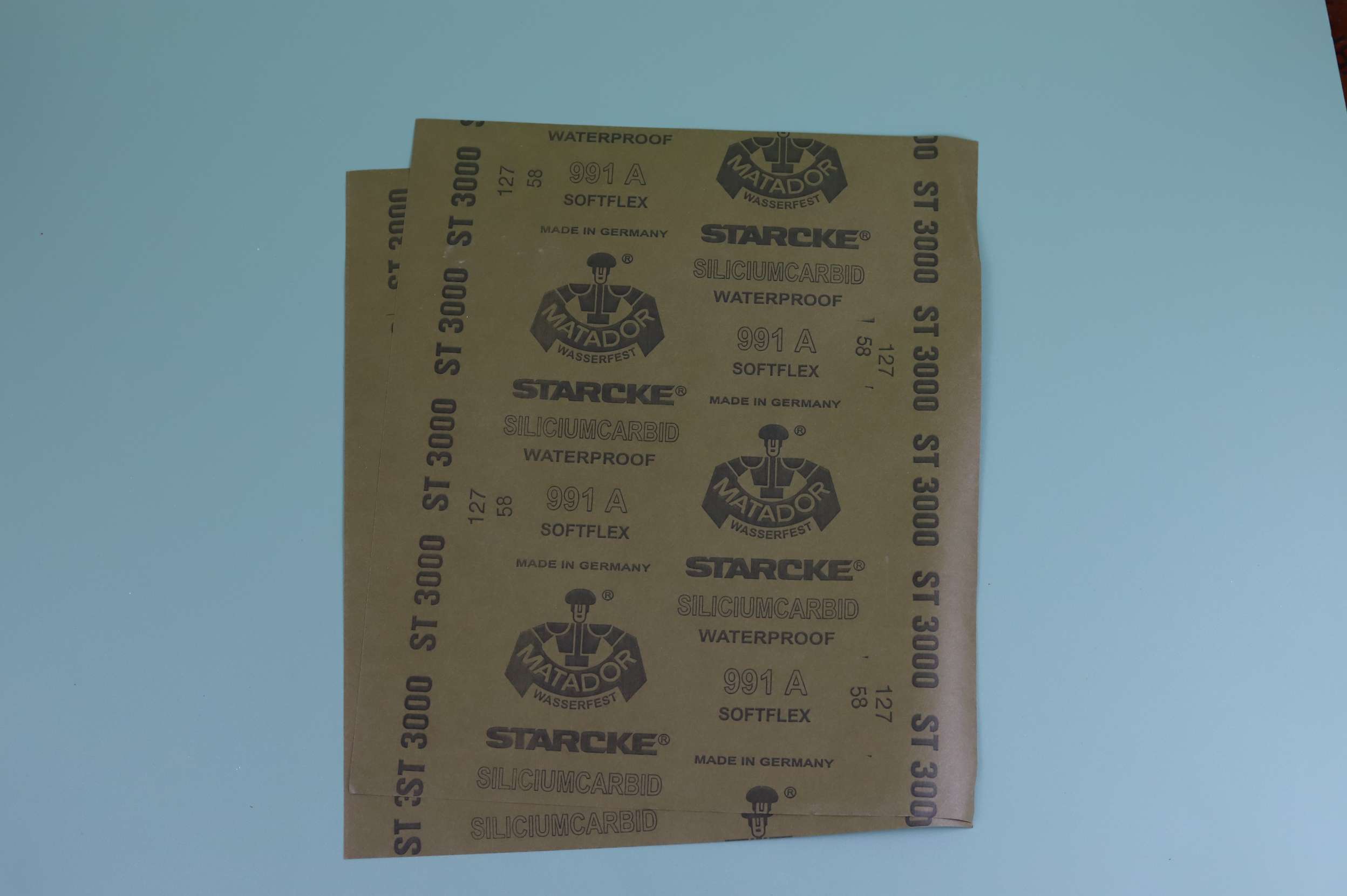

Products Description

- Starcke industrial quality sandpaper strong matador. Premium waterproof abrasive for wet and dry silicon sandpaper. Box contents: 50 pieces.

- Abrasive grit: silicon carbide Bonding: synthetic resin Scatter: dense Special feature: waterproof

- Underlay: latex containing flexible A-paper, waterproof, closure: 100

- For processing the materials: paint, glass, stone, metal.

- Waterproof abrasive on flexible latex paper backing Ideal for the sanding of paints and spatulas in automotive engineering and automotive repair. Produces the highest surface quality on paint, glass and metal surface.

The Matador brand silicon sandpaper material provides you with a high strength product, and a solid finish with a long working life. These Starcke Matador silicon sandpaper sheets work great on all kinds of material, including jewelry, jade, stone inkstone, metal (copper, iron, aluminum, stainless steel and other metal casting), plastic, precision instrument, solid wood, cork, the paint surface conditioning and fine polishing processing. This product features an anti-clogging stearate which provides better sanding and a cleaner, safer working environment.

Matador #400 – #7000

Product Size: 28cm x 23cm (approximately size of A4 paper)

Advantages of silicon sandpaper

Silicon carbide sandpaper, also known as silicon sandpaper, has several advantages over traditional sandpaper made from aluminum oxide. Some of the advantages of silicon carbide sandpaper include:

- Durability: Silicon sandpaper is a harder material than aluminum oxide, making it more durable and longer lasting.

- Faster Cutting: The hardness of silicon sandpaper allows for faster cutting and sanding, making it a more efficient option for heavy-duty sanding tasks.

- Works well on harder materials: Silicon carbide sandpaper is well suited for sanding and polishing harder materials, such as metal and stone.

- Resistant to heat and moisture: Silicon carbide is resistant to heat and moisture, making it a good option for wet sanding and sanding in high-heat environments.

- Can be used for both dry and wet sanding: Unlike aluminum oxide sandpaper, which is typically only used for dry sanding, silicon carbide sandpaper can be used for both dry and wet sanding, giving it more versatility.

Overall, the combination of hardness, durability, and versatility make silicon carbide sandpaper an excellent choice for a variety of sanding and polishing tasks.

Product detail & Main specification

|

Product |

Silicon Carbide Abrasive Sand paper |

|

Material |

Silicone Carbide |

|

Paper Backing |

Kraft Paper, latex paper |

|

Grit |

P60-P3000 |

|

Application |

Perfect for handling every kind of odd jobs and little fixes, like automotive sanding, wood furniture finishing, wood turning |

|

Samples |

Free |

|

Size |

9″*11″ |

Product application

Silicon carbide sandpaper is a popular abrasive product known for its hardness, durability, and versatility in various sanding applications. Here’s an in-depth exploration of silicon carbide sandpaper:

Composition and Characteristics:

-

Hardness: Silicon carbide (SiC) is a hard and brittle crystalline compound with excellent abrasion resistance, making it suitable for tough sanding tasks on harder surfaces like metal, glass, and stone.

-

Heat Resistance: It has exceptional heat resistance, allowing for efficient sanding at high speeds without compromising the abrasive properties of the sandpaper.

-

Aggressive Cutting Action: Silicon carbide abrasive grains have sharp edges that provide aggressive cutting action, allowing for quick material removal, especially on tough materials or surfaces with unevenness.

-

Water Resistance: SiC sandpaper is suitable for wet sanding applications due to its resistance to water and other liquids, making it a preferred choice in automotive sanding processes.

Grits and Applications:

-

Coarse Grits: Silicon carbide sandpaper is available in various grit sizes, including coarse grits suitable for heavy material removal, leveling uneven surfaces, or rust removal on metals.

-

Fine Grits: It also comes in finer grits, suitable for finishing applications where a smooth surface finish is desired, such as polishing metals or refining wood surfaces.

-

Metalworking: SiC sandpaper is commonly used in metalworking for grinding, sanding, and polishing applications on metals due to its hardness and effective material removal.

-

Glass and Stone: It’s highly effective in sanding and smoothing glass and stone surfaces, providing precise finishes without causing damage or scratching.

-

Woodworking: While primarily used in tougher applications, silicon carbide sandpaper is also employed in woodworking tasks for aggressive wood removal or smoothing rough surfaces.

Applications in Various Industries:

-

Automotive Refinishing: Silicon carbide sandpaper is extensively used in the automotive industry for sanding and refinishing bodywork, paint, and metal surfaces due to its durability and efficiency in material removal.

-

Metal Fabrication: It finds applications in metal fabrication shops for grinding and finishing metal surfaces, preparing them for painting, welding, or further processing.

-

Glass Manufacturing: SiC sandpaper aids in smoothing glass edges, removing imperfections, and shaping glass in the manufacturing process.

-

Stone and Concrete Work: In construction and masonry, silicon carbide sandpaper is used for shaping and smoothing stone and concrete surfaces.

Specialty Products and Variants:

Apart from traditional sandpaper sheets, silicon carbide abrasives come in various forms such as sanding belts, discs, rolls, and sanding pads, catering to different sanding equipment and specialized applications.

In conclusion, silicon carbide sandpaper is a versatile abrasive product known for its hardness, heat resistance, and effectiveness in demanding sanding tasks across various industries. Its ability to handle tough materials and offer efficient material removal makes it a preferred choice for professionals in metalworking, automotive refinishing, woodworking, and other applications requiring aggressive abrasion and precise finishes.