Black Cutting Disc Description

- Designed to quickly cut through metal pipes, tubes flat sheets and more

- Exceptional durability extends the life of the wheel for great performance value

- 3M Precision-Shaped Grain cuts exceptionally fast, helping increase productivity

- It may be used on a variety of substrates, such as carbon steel and stainless steel

- Use with tools and accessories designed for cut-off wheels

- For safety, always use on a tool with an approved guard, as per ANSI B7.1

A Cut Above

The 3M™ Silver Cut-Off Wheel Black Cutting Disc is designed to quickly cut through metal pipes, tubes and flat sheets. This may include use in multiple production Cut-off wheels are used in many industries, such as shipbuilding, rail, general metal fabrication and more. You can rely on this wheel to help you tackle your toughest metal cutting applications.

3M Precision-Shaped Grains

The 3M™ Silver Cut-Off Wheel Black Cutting Disc features 3M Precision-Shaped Grain, which continually fractures into super-sharp points and edges that slice cleanly through metal, rather than gouging or plowing as traditional abrasives do. This also helps it to last significantly longer than conventional ceramic grain abrasives while maintaining a high cut-rate over the life of the wheel.

Safety First

This wheel must be attached to a cut-off wheel tool (sold separately) and should always be used with a wheel guard for safety. The wheel also must have a maximum operating speed greater than or equal to the maximum speed of the power tool used.

New 3M™ Silver Abrasives

The 3M™ Silver Cut-Off Wheel Black Cutting Disc is part of a new class of 3M abrasives designed to deliver an unbeatable combination of performance and value. Powered by the legendary speed and long life of 3M Precision-Shaped Grain, these new products are ideal for a wide variety of metalworking applications like weld removal, beveling, edge chamfering and more — offering a longer life and faster cut than aluminum oxide, alumina zirconia and other conventional ceramic abrasives.

Attributes:

The black cutting discs are made of high-quality abrasive grains and resin, ensuring their durability and strength.

Black cutting discs are available in a wide range of diameters. Users can choose flexibly according to their specific needs

Internal 3M testing on 304L stainless steel sheet (11 gauge) using a 13 amp electric tool.

Wheels are tested to end of life.

Experience the power of 3M Precision Shaped Grain to provide a cool, extra-sharp, quick cut long after other wheels are consumed. Unlike coated abrasive discs, which shape or sand objects using the disc surface, cut-off wheels provide perpendicular cuts using the outer edge of the wheel. 3M Precision Shaped Ceramic Grain products have raised the bar for high-performing abrasives. 3M Precision Shaped Grain (PSG) out cuts and outlasts conventional ceramic industrial abrasives and requires less grinding force to achieve superior performance. The result is that operators can make more cuts and complete more parts per disc with less muscle-work and fatigue. PSG also wears evenly, and because the abrasive itself stays cooler and sharper, 3M PSG products last significantly longer than their conventional ceramic counterparts, ensuring extended high performance in production applications.

The 3M black cutting disc is a durable, fast-cutting wheel with a high cut rate and long life. Suitable for cutting almost any material, including fiberglass, stainless steel, and mild steel.

3M black cutting discs use 3M™ ceramic abrasive particles for excellent durability and higher cutting efficiency. The unique crystalline structure of the “stay-sharp” ceramic grains continuously generates new cutting edges on the surface of the workpiece, thus ensuring particularly fast and continuous cutting. Fast and even cutting-edge action helps increase productivity and output. Additionally, the particles can withstand medium to high-pressure production environments, contributing to the long life of the abrasive.

Product detail & Main specification

|

Abrasive Material |

Precision-shaped ceramic |

|

Application |

Cutting, Grinding |

|

Attachment Type |

Center Hole |

|

Bond Type |

Resin |

|

Center Hole Diameter (Metric) |

22.225 mm |

|

Color Family |

Black |

|

Equipment – Machines |

Cut-off Wheel |

|

Form Type |

Right Angle |

|

For Use On |

Carbon steel and stainless steel |

|

Grit |

36 |

|

Industries |

Metalworking |

|

Maximum Speed |

13300 rpm |

|

Overall Diameter (Imperial) |

4.5 in |

|

Overall Thickness (Metric) |

1.143 mm |

|

Position |

Better |

|

Primary Application |

Metalworking |

|

Product Color |

Black |

|

Product Form |

Wheel |

|

Product Type |

Cut-off Wheel |

|

Substrate |

All Metal, Carbon Steel, Cast Iron, high-speed Speed Steel, Non-ferrous Metal, Stainless Steel, Steel, and Steel |

A black cutting disc typically refers to a type of abrasive cutting disc or wheel that is colored black. These discs are commonly used in metalworking and are designed to cut through various types of metal, such as steel, iron, or aluminum.

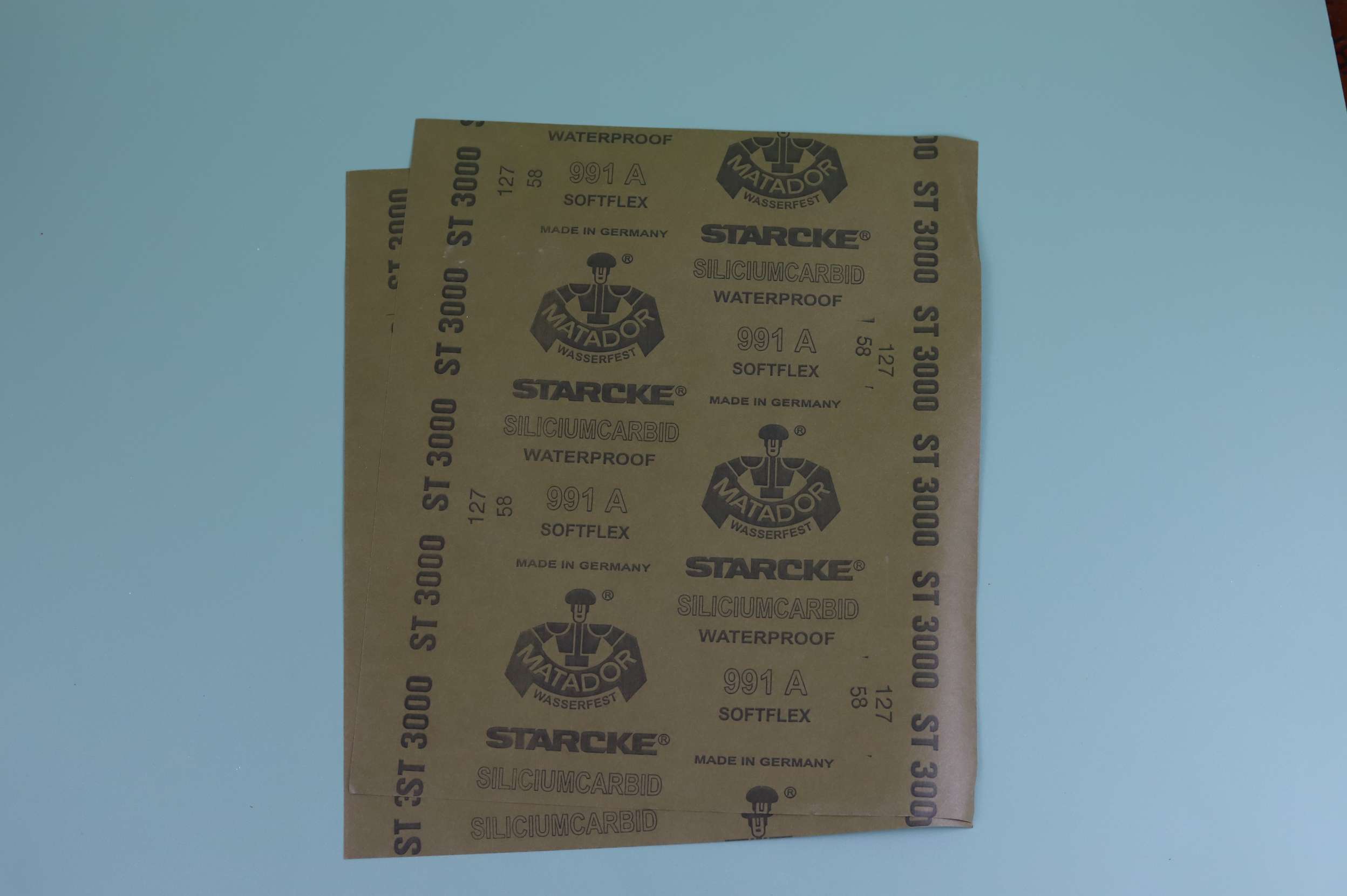

The black color of the cutting disc is often an indication of the type of abrasive material used, such as aluminum oxide or silicon carbide. These abrasive materials are known for their hardness and ability to efficiently cut through metal.

When using a black cutting disc, it’s important to follow proper safety precautions. This includes wearing appropriate personal protective equipment (such as safety glasses, gloves, and a face shield), securing the workpiece properly, and using the disc in accordance with the manufacturer’s instructions.

It’s worth noting that there are various brands and models of black cutting discs available on the market, so the specific features and characteristics may vary. If you’re looking to purchase a black cutting disc, I recommend checking with local hardware stores, industrial suppliers, or online retailers that specialize in metalworking tools and abrasives.

Product Application

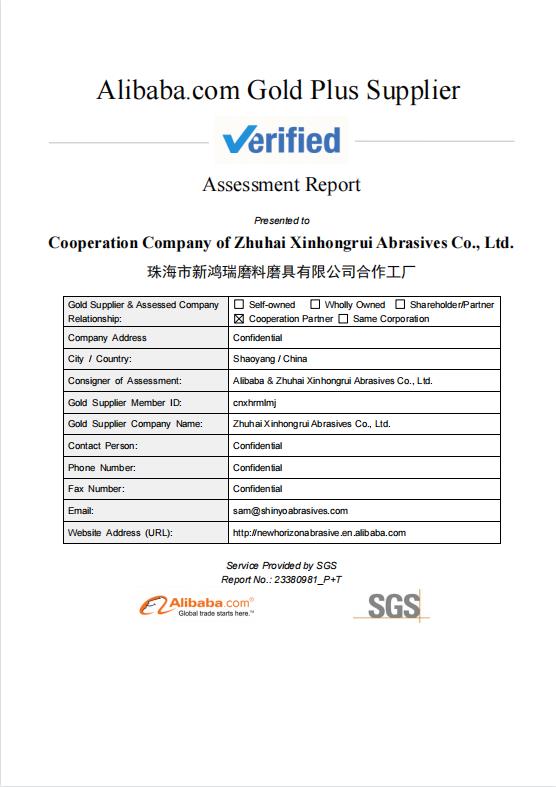

Certificate