Products Description

- 3M Precision Shaped Grain maintains super-sharp points that cut exceptionally fast with less pressure

- Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes

- Triangular-shaped ceramic grain lasts up to two times longer than other ceramic abrasives—it wears evenly, runs cool, and optimizes mineral breakdown

- Stiff fiber backing and a strong resin bond provide durability and tear-resistance for heavyweight applications such as high-pressure weld grinding and beveling

Raising the Bar in Abrasives This premium fiber disc raises the bar in speed and stock removal. With 3M 982C Precision-Shaped Grain, 3M engineers developed a process for generating triangular-shaped ceramic grains that are electrostatically oriented on the backing to form sharp peaks and maximize cutting potential. These peaks act like individual cutting tools that slice through metal and continuously fracture into new, sharp cutting edges. The grains wear evenly and self-sharpen, reducing heat due to friction to deliver up to twice the life of other fiber discs with less grinding pressure.

The result is that the 3M 982C Cubitron™ II Fiber Disc out-cuts and outlasts every conventional ceramic industrial abrasive disc on the market, maximizing productivity and helping reduce your overall abrasive spend. Ideal for Robotic Weld Grinding In medium- and high-pressure applications like robotic weld grinding, it’s important to choose a high-performance abrasive that cuts fast and lasts long. The self-fracturing mineral in 3M™ Cubitron™ II Fibre Disc 982C will keep your robot grinding welds long after other abrasives call it quits, reducing downtime and maximizing efficiency.

Curious about robotic material removal? Our dedicated team of 3M robotics application engineers is ready to partner with you on your automation journey, from idea to implementation. Choose Your Grit 3M 982C Cubitron™ II Fibre Disc comes in a range of grits to suit your application needs, from coarse grinding large welds to blending and deburring. Your Total Solution Supplier Combined with 3M power tools and application engineering expertise, the 3M™ Cubitron™ II Fibre Disc 982C is part of a complete abrasive solution. With the 3M abrasive solution, you’ll have the right abrasives, the right tools, and industry-leading application engineers to help you take your shop to the next level.

3M 982C Cubitron Fiber Disc is made of synthetic resin as adhesive, and the abrasive is bonded to the surface of special high-strength steel paper. Equipped with portable pneumatic and electric polishers for metal or non-metal derusting, deburring, polishing, dry and wet processing, and grinding.

3M 982C Cubitron Fiber Disc Features:

The special CUBITRON II material makes the grinding work more labor-saving, suitable for carbon steel pre-welding pretreatment or weld removal, has good heat dissipation, has an optimized abrasive design that reduces post-processing difficulty, and is not easy to burn the workpiece.

Improve the output per unit time with self-sharpening, 3M precision molding abrasive technology ensures sharp cutting efficiency and uniform wear, shortening the delivery cycle; using fewer sand discs, reducing labor intensity and cost;

Product detail & Main specification

|

Attachment Type |

Center Hole |

|

Backing Material |

Fibre |

|

Bond_Type |

Resin |

|

Brand |

Cubitron™ |

|

Center Hole Diameter (Metric) |

22.225 mm |

|

Coat Type |

Closed Coat |

|

Grit |

60+ |

|

Hole Configuration |

700BB |

|

Industries |

Machinery Manufacturing, Metal Fabrication, Transportation |

|

Max Speed |

8600 rpm |

|

Mineral Type |

Precision Shaped Ceramic |

|

Overall Diameter (Metric) |

177.8 mm |

|

Product Form |

Disc |

|

Sub Industries |

Farms & Construction, Industrial, Oil & Gas, Rail, Sheet Metal, Ship & Boat Building, Specialty Vehicle, Structural Steel |

Product application

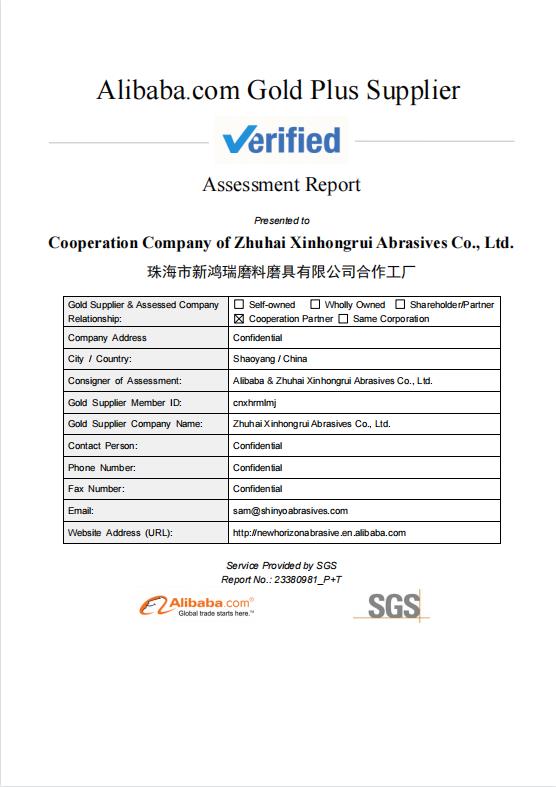

Certificate

The 3M 982C is a premium-grade ceramic abrasive flap disc manufactured by 3M, a renowned leader in industrial abrasives and materials. This flap disc is engineered to deliver exceptional performance and durability in a wide range of metalworking applications.

Features and Composition

Ceramic Abrasive Grain:

- The 3M 982C features an advanced ceramic abrasive grain that offers outstanding cutting capability and extended product life compared to conventional abrasives.

- This grain is known for its superior hardness, toughness, and heat resistance, ensuring consistent performance in demanding applications.

Precision Shaping of Flaps:

- The precisely shaped flaps are designed for optimal contact with the work surface, resulting in efficient material removal and a smoother finish.

- The configuration of these flaps reduces heat buildup, minimizing the risk of discoloration or warping on the workpiece.

Resin Bonding and Backing Material:

- The abrasive flaps are securely bonded to a durable fiberglass backing plate using a high-performance resin.

- The backing material provides flexibility and stability, allowing the disc to conform to irregular surfaces while maintaining structural integrity.

Specifications and Variants

The 3M 982C flap disc is available in various configurations to meet diverse application needs:

- Grit Sizes: Offered in a range of grit sizes from coarse to fine, allowing users to choose the appropriate level of abrasiveness for different tasks.

- Diameter and Arbor Size: Available in multiple diameters and compatible with various angle grinders or power tools equipped with corresponding arbor sizes.

- Flat or Conical Shape: Depending on the application, users can select either a flat or conical shape for improved access to tight spaces.

Applications

The 3M 982C flap disc is well-suited for an array of metalworking tasks, including but not limited to:

Deburring and Edge Blending:

- Removing sharp edges, burrs, or excess material from metal parts for a smoother, safer finish.

- Blending welded seams seamlessly results in a uniform surface appearance.

Surface Preparation and Finishing:

- Preparing metal surfaces before painting, coating, or further processing by achieving a clean and uniform finish.

- Achieving desired surface textures or finishes on metals for aesthetic or functional purposes.

Stock Removal and Shaping:

- Efficiently removing material from metal surfaces or shaping metal components to desired specifications.

Advantages of 3M 982C Abrasive Flap Disc

Enhanced Performance:

- The advanced ceramic abrasive grain delivers exceptional cutting power and longer product life, improving overall efficiency and productivity.

- Provides faster material removal and achieves smoother finishes compared to traditional abrasives.

Durability and Longevity:

- The 3M 982C exhibits superior durability, reducing the frequency of disc changes and increasing cost-effectiveness.

- Withstands high temperatures, reducing the risk of premature wear or damage during demanding applications.

Versatility and Consistency:

- Suitable for use on various metals, including stainless steel, carbon steel, and alloys, offering consistent performance across different materials.

- Maintains its cutting efficiency and performance throughout its lifespan, ensuring consistent results.

Considerations and Best Practices

To optimize the use of 3M 982C flap discs and ensure safety and effectiveness, users should consider the following:

- Safety Precautions: Prioritize safety by wearing appropriate personal protective equipment (PPE) like gloves, eye protection, and a face mask to shield against debris.

- Optimal Operating Conditions: Operate within the recommended speed range for the disc size and avoid excessive pressure to prevent overheating and premature wear.

- Tool Compatibility: Ensure compatibility with the angle grinder or power tool being used to avoid issues or potential damage.

- Storage and Handling: Store the flap discs in a dry, controlled environment to maintain their performance and shelf life.

The 3M 982C abrasive flap disc stands out as a high-performance and durable abrasive tool designed for professionals seeking superior results in metalworking applications. Its advanced ceramic abrasive grain, precision flap design, and versatile applications make it a valuable asset in various industries where efficiency, consistency, and quality are paramount.

Why Choose 3M 982C Sanding Paper?

- Exceptional Cutting Power: Precision-shaped ceramic grain for faster, more efficient material removal.

- Long-Lasting Durability: Extended sanding life reduces replacement frequency and enhances productivity.

- Versatile Use: Suitable for a wide range of applications across various industries.

- Consistent Performance: Delivers uniform results with less effort, ensuring a high-quality finish.

- Ease of Application: Compatible with various sanding tools and machines, providing a smooth sanding experience.

- Health and Safety: Designed to minimize dust generation and reduce user fatigue.

How to extend the service life of 3m 982c sanding paper

Extending the service life of 3M™ 982C Sanding Paper involves proper usage, maintenance, and handling practices. Here are several tips and best practices to help you get the most out of your sanding paper:

1. Proper Grit Selection

Choosing the right grit for your application is crucial. Using a grit that is too fine for heavy material removal will wear out the sanding paper prematurely. Conversely, using a coarse grit for finishing can damage the surface and reduce the lifespan of the paper. Match the grit to the task at hand to optimize efficiency and longevity.

2. Optimal Pressure Application

Applying excessive pressure while sanding can cause the abrasive grains to wear out quickly and generate more heat, leading to clogging and potential damage to the sanding paper. Use moderate pressure to allow the abrasive grains to do the work. Let the sanding tool’s weight and the abrasive’s cutting power handle the material removal.

3. Maintain Proper Sanding Angle

Keeping the sanding paper at the correct angle relative to the surface can prevent uneven wear. For handheld sanders, maintaining a flat contact surface ensures even distribution of pressure, which helps extend the paper’s service life.

4. Use of Lubricants

In some sanding applications, using a lubricant like water or a specially formulated sanding lubricant can reduce friction and heat buildup, which can extend the life of the sanding paper. This is especially useful in wet sanding processes for metals or automotive finishes.

5. Dust Management

Dust and debris can clog the abrasive surface, reducing its effectiveness and lifespan. Use a vacuum system or compressed air to keep the sanding area clean. Regularly clearing dust from the sanding paper and the work surface will help maintain optimal cutting performance.

6. Avoid Overheating

Heat is a major factor that can reduce the lifespan of sanding paper. Overheating can cause the abrasive grains to break down and the adhesive to weaken. Ensure adequate ventilation and cooling, and take breaks to let the sanding paper cool down if it becomes too hot.

7. Clean the Sanding Paper

For sanding paper that clogs easily, especially in wood or paint applications, use cleaning sticks or abrasive cleaning blocks. These tools help remove buildup from the sanding paper, restoring its cutting ability and extending its service life.

8. Use Sanding Backing Pads

Using proper backing pads can provide better support and more even pressure distribution, which helps extend the life of the sanding paper. Ensure that the backing pad is in good condition and compatible with the sanding paper and tool.

9. Rotate and Replace Paper When Necessary

Even with proper care, sanding paper will eventually wear out. Rotate the sanding paper to use fresh areas if possible, and replace it when it no longer performs effectively. Continuing to use worn-out paper can damage the surface being worked on and reduce efficiency.

10. Store Properly

Proper storage of sanding paper can also affect its lifespan. Store the sanding paper in a cool, dry place, away from direct sunlight and moisture. Keeping it flat or in a way that prevents creases or bends will maintain its usability.

11. Use the Right Tool Settings

For power sanders, using the correct speed setting can make a significant difference. Too high a speed can generate excessive heat and wear out the sanding paper quickly. Follow the manufacturer’s recommendations for speed settings based on the material and application.

12. Work on Clean Surfaces

Before starting the sanding process, ensure that the surface is clean and free of large debris or contaminants. This prevents the abrasive grains from getting damaged or clogged quickly.

13. Regular Inspection

Regularly inspect the sanding paper for signs of wear, clogging, or damage. Addressing issues early can prevent further damage and extend the paper’s service life.

By following these best practices, you can maximize the efficiency and longevity of your 3M 982C Sanding Paper. Proper selection, handling, and maintenance not only extend the life of the sanding paper but also enhance the quality of your work, reduce costs, and improve overall productivity. Investing a little time in proper care and technique goes a long way in ensuring optimal performance from your sanding paper.