Descrizione dei prodotti

- Aluminum oxide abrasive provides a fast cut, long life and professional results

- Discs can last 2-3 times longer than traditional discs

- Stearate coating helps resist loading for extended performance

- Spiral-patterned design features many small holes for dust extraction and reduced loading

- Multi-hole disc pattern eliminates hole alignment for quicker changes, longer disc life

- 3M™ Hookit™ attachment system makes for fast, efficient disc change-outs

Built for Longer Disc Life

So much technology in one abrasive disc: our 3M™ Hookit™ Purple Clean Abrasive Sanding Discs 334U cuts fast, lasts long, resists loading and leaves a consistent finish across a wide range of applications. It features durable, fast-cutting aluminum oxide abrasive built on C-weight paper backing. A spiral pattern, made up of many tiny holes, keeps particulates away from the surface to reduce loading. When used with dust extraction systems dust will be captured rather than staying on the sanding surface or floating in the air. This pattern also eliminates the need for hole alignment, making it faster and easier to change the sanding discs and extending the abrasive’s useful life. Discs are available in grades P240 – P800, ideal for featheredging, fine featheredging or as a last step before priming. They are also great for prepping before blending. Our Hookit™ attachment system makes for fast and efficient disc change-outs without tools.

Chevron Hole Configurations

To achieve maximum performance, 3M has added small holes that have been purposely arranged on the sheet in a chevron formation. This configuration of holes allows for optimal particulate removal from the face of the sheet, improving performance when used with or without a dust extraction system. When using dust extraction, sheet alignment is not necessary to achieve direct air flow from the panel through the abrasive sheet, saving time.

Hard, Tough and Sharp

3M’s fast cutting, long lasting abrasive saves labor costs and improves quality. Aluminum oxide is popular among collision repair professionals because of its fast cut-rate and long life. A natural mineral, it makes a tough, durable abrasive that stays sharp longer. Aluminum oxide is suitable for a wide variety of metalworking materials including ferrous alloys. These discs sand fast to improve technician productivity and reduce labor costs, and the consistent finish reduces rework further improving repair efficiency.

Our Kiss-Cut Underscore Technology

The unique Kiss-cut Underscore Technology enables technicians to quickly and easily convert Purple abrasive sheet rolls into multiple sheet-length configurations. Sheets are perforated to match a range of accessories. Technicians simply snap the sheet off at the perforations to most closely match the hand or file board for each specific application. This makes for more effective sanding and reduces material waste.

Our Hookit™ Attachment System

3M offers a complete line of hook-and-loop style Hookit™ sanding discs for work spaces where adhesive backing may become contaminated by dust, dirt, or flying debris. Hookit™ sanding discs conveniently and firmly attach to a hook-and-loop backup sanding discs pad (sold separately). It’s simple: just attach the disc to the backup pad and start sanding. It removes just as easily and cleanly, and can be re-used again and again for the extent of the abrasive life. To ensure easy, fast attachment, the precise spiral multi-hole pattern of the 3M™ Hookit™ Purple Clean Sanding Abrasive Disc 334U does not require hole alignment with the back-up pad.

Spiral Hole Pattern Helps You Get More from Each Disc

To achieve maximum performance, the discs are designed with small spiral-patterned holes to give dust a better escape route, moving more dust away from your finishing surface without loading the disc.

The spiral hole configuration allows for optimal particulate removal improving performance when used with or without a dust extraction system. When using dust extraction, hole alignment is not necessary to achieve direct air flow from the workpiece through the abrasive disc. Technicians can change these discs more quickly, saving time and promoting re-use, helping preserve abrasive life. In fact, 3M™ Hookit™ Purple Clean Sanding Abrasive Disc 334U can last 2 – 3 times longer than other discs — delivering professional results while improving the bottom line in collision repair.

Better Science for Better Sanding from 3M

The 3M™ Hookit™ Purple Clean Abrasive Sanding Discs 334U carries our Purple designation which indicates the latest 3M technology, greatest performance and highest quality available in an abrasive disc. From its fast-cutting abrasive to its unique spiral-patterned hole design, this disc combines performance, durability and long-lasting efficiency for improved throughput across your entire collision repair operation. It’s another example of what 3M does best: Science. Applied to Life.

The Power of Purple

The 3M™ Hookit™ Purple Clean Sanding Abrasive Sheet Roll 334U carries our Purple designation which indicates the latest 3M technology greatest cost/value and highest quality available in an abrasive sheet roll. From its high-performance aluminum oxide abrasive to its perforated Kiss-cut Underscore Technology to its clean sanding chevron hole pattern and innovative hook and loop attachment, this sheet delivers improved throughput across your entire collision repair operation.

What 3M Purple Cleaner Sandpaper can do for you:

Longer Disc Life – Can last 2-3 times longer than traditional non-porous, 5-or 6-well discs.

Increased Productivity – More durable use of discs, increased productivity and unique porous disc pattern design to change quickly because hole alignment is not required. In terms of material consumption, you will see the difference.

Load more dust with fewer discs – Helical disc design, with hundreds of holes to give dust a better escape route, will remove more dust from your finishing surface without loading the disc. Dust settles into the circulation of the disc, not in the air or on the disk surface. Increased cutting capacity – Advanced abrasives provide consistent performance.

Simplify the application of optical discs – Optical discs use the 3MHookit accessory system for easy reuse. Before use, primer sanded or preping mixed.

Design: Resin-bonded abrasive grain (A) on paper, smooth and open grained. Dust-repellant Fre-Cut? coating and the hole structure in conjunction with Hookit?-adhesive backing pads prevents premature clogging and clearly increases life span and removal performance.

Application: Universal abrasive suitable for any coarse, medium and fine grinding on all hard and soft wood, synthetic and metal surfaces as well as for paint and filler sanding.

Note: Adhesive backing discs see (Order No. 8212).

With aluminium oxide abrasive grain and fine perforations.

Advantages of Aluminum Oxide Abrasives

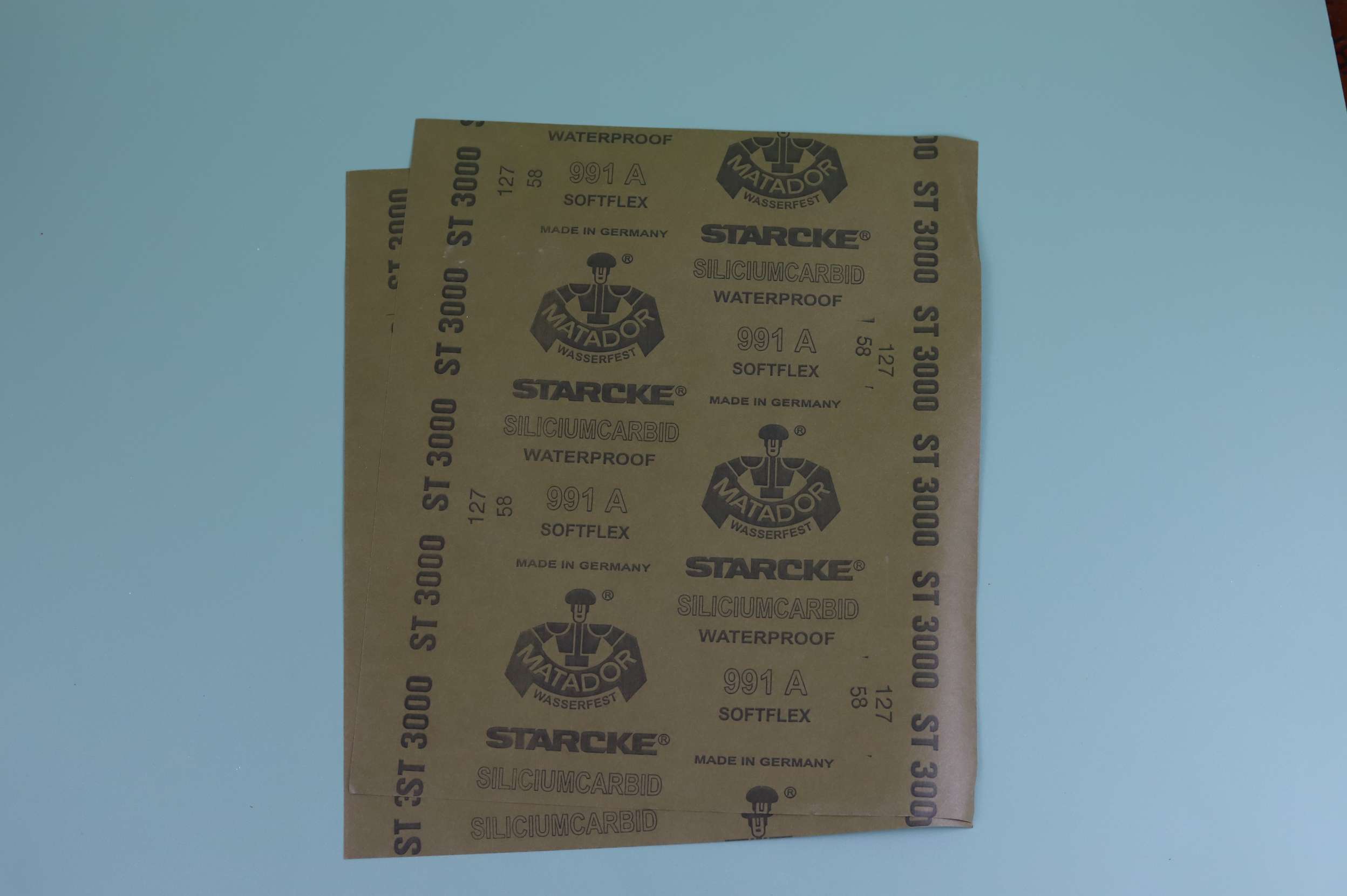

There are many types of abrasives, such as green silicon carbide, black silicon carbide, brown corundum, white corundum, diamond and so on. Among them, aluminum oxide is one of the most economical abrasives. Alumina abrasive has sharp edges and high density, its hardness is second only to diamond, and it can be used in both dry and wet processing processes. It can smooth the rough surface of the workpiece and is one of the fastest cutting abrasives. It can be used for the roughest cuts or pebbled for sanding of delicate workpieces.

As a blasting abrasive, alumina can be recycled, but the specific number of cycles is related to the grade of the material and the specific production process. From the perspective of applicable equipment, most standard abrasive blasting equipment can be applied.

From the perspective of applicable fields, alumina abrasives can be used in aerospace, automobile, consumer product processing, casting/die casting, semiconductor and other fields.

From the perspective of applicable process range: dry grinding and wet grinding; grinding of minerals, metals, glass and crystals; deburring of aluminum and alloy products, descaling of pots; surface electroplating, pretreatment before painting; pretreatment before metal blasting; cleaning of molds; precision optical refraction; glass engraving and paint additives can all use aluminum oxide.

Dettaglio prodotto e specifiche principali

|

Materiale abrasivo

|

Ossido di alluminio

|

|

Disponibilità di vendita alternativa

|

2. Questo prodotto può essere venduto a consumatori e industrie e non ci sono restrizioni sui COV.

|

|

Applicazione

|

Clear Coat Blending, Featheredging, Rimozione dei difetti di verniciatura, Preparazione della vernice, Primer Sanding

|

|

Tipo di attacco

|

Gancio e anello

|

|

Materiale di supporto

|

Carta

|

|

Peso del supporto

|

C Peso

|

|

Marchio

|

3M™, Hookit™

|

|

Quantità di casse

|

4 cartoni per astuccio

|

|

Tipo di cappotto

|

Cappotto chiuso

|

|

Famiglia di colori

|

Purple

|

|

Forma convertita

|

Disco

|

|

Tipo di modulo

|

Clean Sanding

|

|

Grado

|

Fine, Medium

|

|

Gamma di voti

|

Fine (P500-P3000 +5000), Medium (P150-P400)

|

|

Grinta

|

P240, P400, P500, P600, P800

|

|

Number of Vacuum Holes

|

133, 170, 280, 79

|

|

Numero per interno

|

1 per Carton, 50 per Carton

|

|

Diametro complessivo (imperiale)

|

3 in, 5 in, 6 in

|

|

Diametro complessivo (metrico)

|

127 mm, 152,4 mm, 76,2 mm

|

|

Forma confezionata

|

In scatola

|

|

Livello di prestazione

|

Il meglio

|

|

Colore del prodotto

|

Purple

|

|

Forma del prodotto

|

Disco

|

|

Metodo di levigatura

|

Mano, Machine

|

|

Superficie di levigatura

|

Vernice trasparente, Fiberglass, Filler, Vernice, Plastica, Primer

|

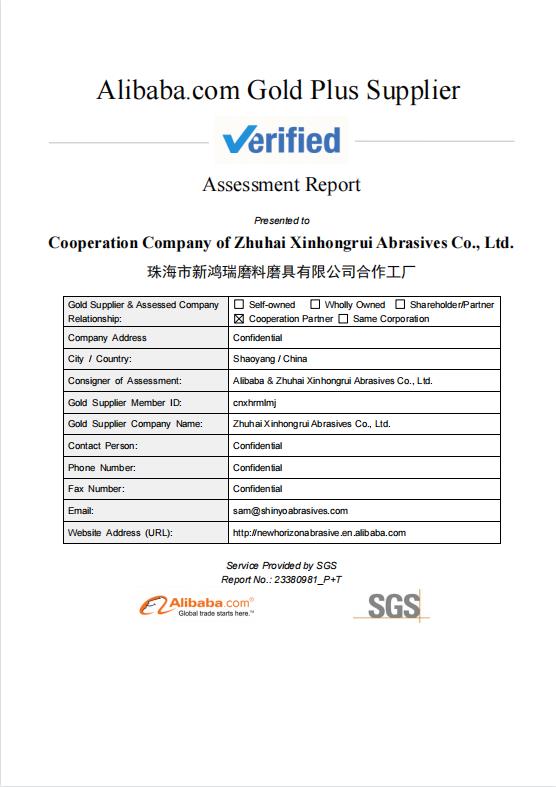

Ccertificato