Description des produits

- Wheel edge can be dressed for effective deburring, finishing and polishing of all metal alloys and many plastics and composites

- Tough, layered, unitized construction can operate clockwise or counterclockwise directions

- Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing

- Densities and grades ranging from soft and conformable to hard and aggressive offer utility for a wide variety of applications

- Resists smearing for cleaner surfaces and less preparation

- Minimizes heat build-up to lessen impact on heat-sensitive materials

Consistent Performance on a Variety of Substrates

Scotch brite unitized wheel gives a clean edge without smearing, reducing the need for additional clean up and preparation. Designed for optimal performance on a die grinder, the scotch brite unitized wheel minimizes heat buildup during operation, making it ideal for use on heat sensitive materials.

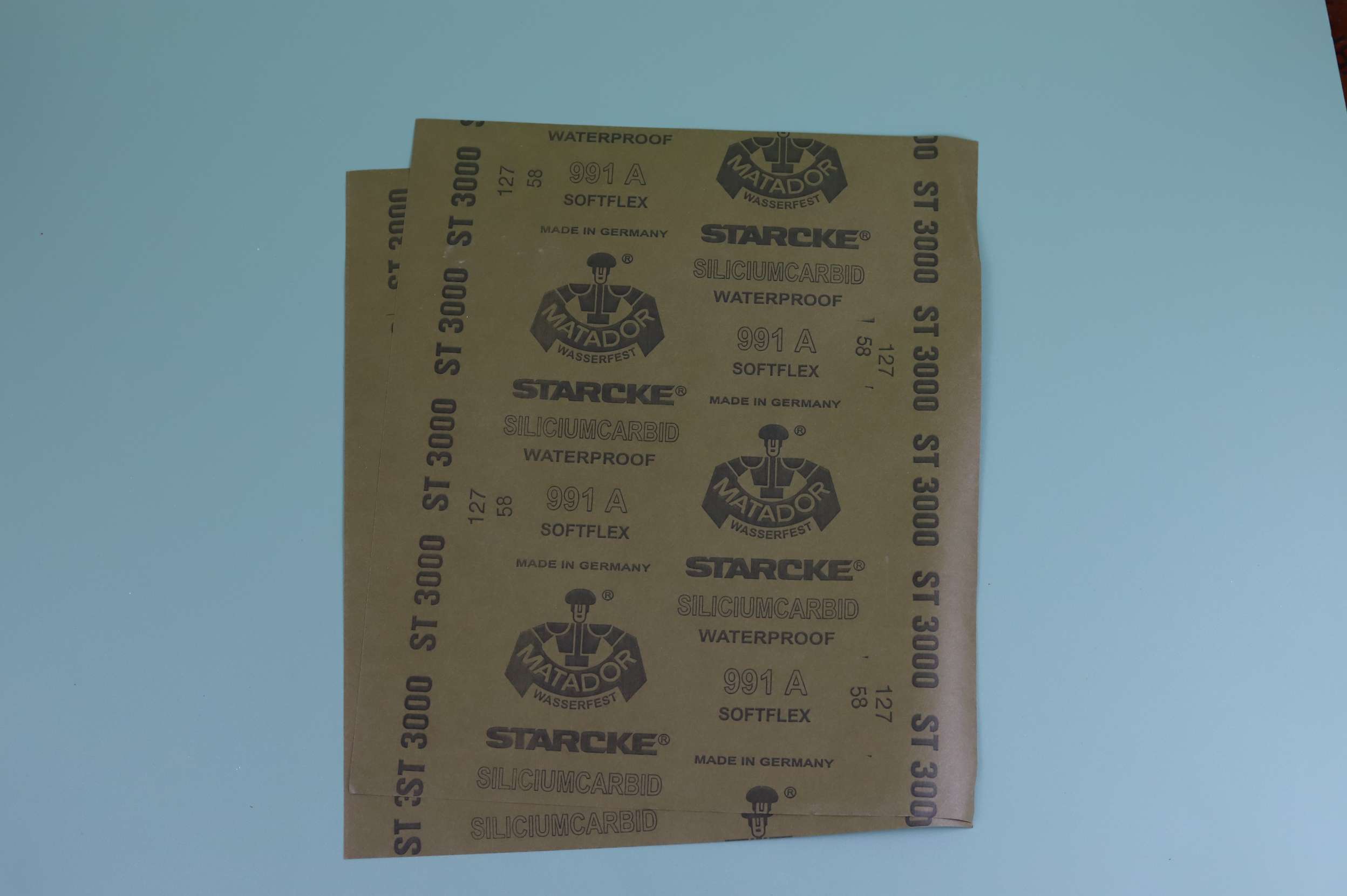

Our scotch brite unitized wheel is filled with abrasive minerals to quickly smooth edges of metal, plastic and composites. It is available with aluminum oxide in fine, medium, coarse and extra coarse grades, and silicon carbide in very fine and fine grades.

Ideal for Robotic Deburring

With a wide range of conformability options and high consistency, long-lasting Scotch-Brite™ industrial abrasives are a great option for robotic deburring. Scotch brite unitized wheel quickly removes burrs and sharp edges in end-of-arm tooling operations, delivering consistent performance through the full life of the abrasive.

Scotch-Brite™ offers unique surface conditioning products with abrasives incorporated into nonwoven nylon fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results over the life of the product. We chose an open-web material that is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.

Détail du produit et spécifications principales

|

Matériau abrasif

|

Oxyde d'aluminium, Silicon Carbide

|

|

Disponibilité de la vente alternative

|

6. Ce produit est destiné à un usage industriel uniquement et il n'y a pas de restrictions concernant les COV.

|

|

Application

|

ÉbavurageFinitionPolissage

|

|

Type de pièce jointe

|

Trou central

|

|

Marque

|

Scotch-Brite™

|

|

Diamètre du trou central (impérial)

|

0.063 in, 0.12 in, 0.125 in, 0.188 in, 0.25 in, 0.37 in, 0.375 in, 0,5 in, 0.625 in, 0.75 in, 0.875 in, 1 in, 1.25 in, 1.5 in, 5 in

|

|

Diamètre du trou central (métrique)

|

1.588 mm, 12,7 mm, 127 mm, 15.875 mm, 19,05 mm, 22.225 mm, 25,4 mm, 3.048 mm, 3.175 mm31,75 mm, 38,1 mm, 4.763 mm, 6,35 mm, 9.398 mm, 9,525 mm

|

|

Famille de couleurs

|

Beige, Brown, Gray

|

|

Densité

|

2, 3, 4, 6, 8

|

|

Équipement - Machines

|

Meuleuses sans centreMeuleuses de matricesSanders en ligne, Inline SandersBéquille manuellePression Assit Backstand

|

|

Largeur de la face (impériale)

|

0.125 in, 0.188 in, 0.25 in, 0.375 in, 0,5 in, 0.625 in, 0.75 in, 1 in

|

|

Largeur de la face (métrique)

|

12,7 mm, 15.875 mm, 19,05 mm, 25,4 mm, 3.175 mm, 4.763 mm, 6,35 mm, 9,525 mm

|

|

Type de formulaire

|

Convolution/ébavurage, Unitized, Wheel

|

|

A utiliser sur

|

Tous les métaux, CompositesVerre, Verre, Hard Composite, Soft Composite

|

|

Grade

|

Grossière, Extra Coarse, Fine, MoyenTrès bon

|

|

Diamètre global (métrique)

|

101,6 mm, 12,7 mm, 127 mm, 152,4 mm, 177.8 mm, 19,05 mm, 203,2 mm, 25,4 mm, 254 mm, 304.8 mm31,75 mm, 355.6 mm, 38,1 mm, 50,8 mm, 63,5 mm, 76,2 mm

|

|

Couleur du produit

|

Marron, Gray, Tan

|

|

Forme du produit

|

Roue

|

|

Taille

|

152mm x 12mm x 12.7mm, 152mm x 6mm x 12.7mm, 38mm x 3mm x 4.8mm, 51mm x 12mm x 6.35mm, 76mm x 12mm x 6.35mm

|

|

Substrat

|

Tout métalCompositeVerre, Verre

|

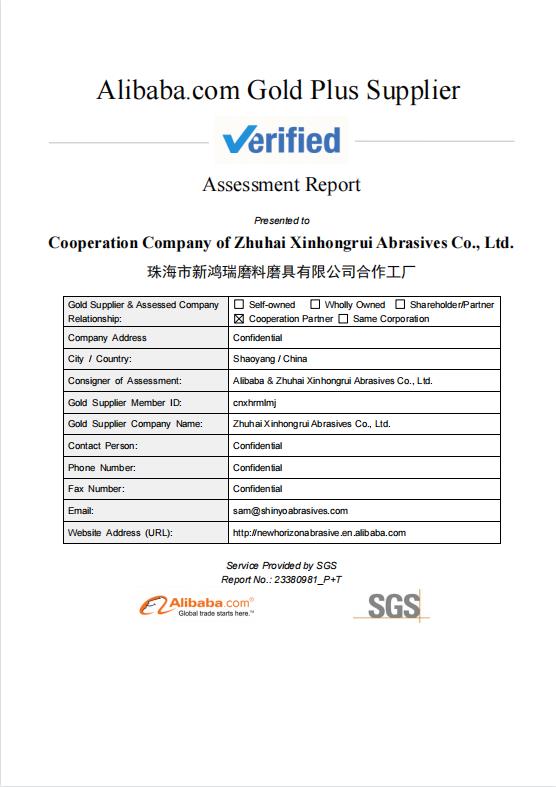

Certificat