Products Description

- 2-IN-1 TIMESAVER: Built to grind and blend small welds in a single step, as well as blend, deburr, finish and refine workpieces

- AGGRESSIVE CUTTING ACTION: Tough enough for the heaviest surface conditioning jobs, including blending coarse grind lines

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: The quick change attachment system allows for fast disc changes

- LONG-LASTING DURABILITY: Engineered to resist edge wear for longer disc life

- FAST, CONSISTENT CUT: Ceramic aluminum oxide blends grind lines fast and stays sharp over the life of the disc

- CHOOSE YOUR GRADE: Available in Heavy Duty (HD-CRS) and Super Duty (SD-CRS) to match your application needs

Eliminate steps Save Time

Scotch-Brite quick change light grinding and blending Quickly Change Discs can often single-handedly prepare surfaces for painting where a 3 mil or greater paint thickness is being applied without adding a final dual-action sanding step.

Tough and Sharp

3M™ Quickly Change Discs ceramic aluminum oxide abrasive is a ceramic mineral designed using our proprietary process to enhance the toughness and hardness of the grain for a higher level of performance. The ceramic aluminum oxide blend is engineered to fracture frequently and surpasses aluminum oxide abrasives in both cut-rate and durability. Perfect for moderate-to-heavy stock removal as well as finishing, ceramic abrasives are built to cut fast and handle intense heat and stress applications.

The TN Quick Change Advantage

Quick change Light grinding and blending discs with a TN attachment are designed to allow operators to conveniently change discs fast and easily to accommodate different tasks or multi-step finishing processes. The TN attachment provides a secure attachment even for heavy-duty applications, and the variety of available discs allows swapping from one application to the next in seconds. Each disc is also color-coded to identify its grade, making it easy to grab the grade required for different applications.

Product detail & Main specification

|

Abrasive Material |

Ceramic Aluminum Oxide |

|

Application |

Blending, Deburring, Grinding |

|

Attachment Type |

TN |

|

Brand |

Scotch-Brite™ |

|

Color Family |

Blue |

|

Equipment – Machines |

Right-Angle Grinders |

|

Grade |

Super Duty Coarse |

|

Industries |

Food & Beverage, General Industrial, Heavy Industrial, Machinery Manufacturing, Manufacturing, Metal Fabrication, Metalworking, Paint Preparation, Transportation & Heavy Equipment |

|

Maximum Speed |

13300 rpm |

|

Overall Diameter (Imperial) |

4.5 in |

|

Overall Diameter (Metric) |

114.3 mm |

|

Product Color |

Blue |

|

Product Form |

Disc |

|

Substrate |

All Metal |

Advantages of quickly change discs

There are several advantages to being able to quickly change discs on power tools:

- Time-saving: Quickly change discs allows you to switch between different types of cutting or grinding tasks without wasting time. This is particularly beneficial when working on projects that require multiple disc changes or involve various materials.

- Efficiency: Quickly change discs minimizes downtime, enabling you to maintain a steady workflow and increase productivity. You can swiftly transition from one cutting or grinding application to another, optimizing your work efficiency.

- Versatility: With the ability to change discs promptly, you can use a single power tool for a wide range of applications. Whether you need to switch between cutting metal, grinding concrete, or sanding wood, quick disc changes make it convenient to adapt to different tasks without needing multiple tools.

- Flexibility: The ability to quickly change discs provides flexibility in adjusting the level of aggressiveness or fineness of your work. By easily swapping out discs, you can select the appropriate grit or cutting style to achieve the desired results.

- Convenience: Quickly change discs simplifies tool maintenance and cleaning. If a disc becomes worn out or damaged, you can swiftly replace it, ensuring that your power tool remains in optimal condition for continued use.

Overall, the advantages of quickly change discs include time savings, increased efficiency, enhanced versatility, improved flexibility, and added convenience. These benefits contribute to a smoother workflow, allowing you to tackle different tasks effectively with minimal interruptions.

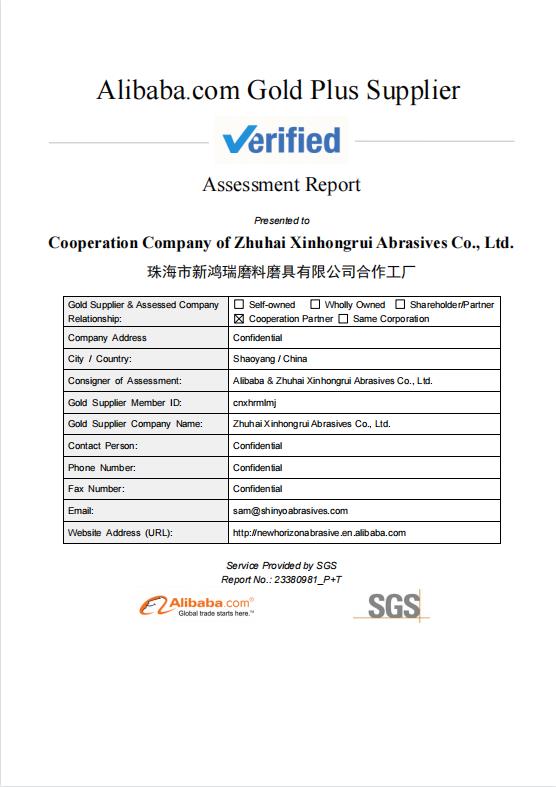

جertificate

Understanding Quickly Change Discs

Quick Change Discs, also known as Roloc discs or Speed-Lok discs, are innovative abrasive discs engineered for seamless mounting and dismounting on compatible backing pads or mandrels. They feature a unique attachment system that allows for quick and tool-free assembly, enabling operators to swiftly switch between discs without downtime.

These discs come in various diameters, grit sizes, and abrasive materials, catering to different applications and surface finishing requirements. Common abrasive materials used in quick change discs include aluminum oxide, ceramic alumina, zirconia alumina, and silicon carbide, each offering distinct properties suitable for specific tasks and materials.

Advantages and Features

1. Rapid Changeover

The standout feature of quickly change discs is their swift attachment and removal mechanism. The innovative design facilitates a toolless process, allowing operators to change discs in seconds. This rapid changeover minimizes downtime, maximizing productivity in various industrial settings.

2. Versatility in Applications

Quick change discs find applications across a wide array of industries, including metalworking, woodworking, automotive, aerospace, and more. From deburring and blending to grinding and polishing, these discs accommodate diverse surface finishing tasks on materials such as metals, plastics, composites, and wood.

3. Compatibility and Interchangeability

Designed for compatibility with various tools, these discs are adaptable to different backing pad systems and mandrels. This interchangeability ensures that the same disc can be used with different tools, offering flexibility and convenience to operators using multiple machines.

4. Assortment of Grit Sizes and Abrasive Materials

The availability of different grit sizes and abrasive materials allows operators to select discs tailored to their specific surface finishing requirements. Coarser grits are suitable for rapid material removal, while finer grits excel at achieving smoother finishes on surfaces.

5. Durability and Longevity

Quickly change discs are engineered to withstand demanding applications. The high-quality abrasive materials and sturdy construction ensure durability and extended usability, reducing the frequency of disc replacements and overall maintenance costs.

Applications Across Industries

1. Metalworking

In metalworking operations, quick change discs are used for deburring, weld blending, edge chamfering, and surface preparation. Their ability to swiftly remove imperfections and achieve smooth finishes makes them indispensable in metal fabrication shops and automotive manufacturing.

2. Woodworking and Carpentry

Woodworkers quickly change discs for shaping, sanding, and finishing wooden surfaces. From refining edges to smoothing intricate details, these discs offer precision and speed, enhancing the quality of woodworking projects.

3. Aerospace and Automotive

In the aerospace and automotive industries, precision is paramount. Quick-change discs aid in preparing surfaces for coatings, refining aircraft components, and achieving flawless finishes on vehicle body panels, ensuring both aesthetic appeal and functional integrity.

4. Construction and Renovation

Builders and contractors quickly change discs for surface preparation tasks during construction and renovation projects. Whether it’s smoothing concrete, removing paint, or preparing surfaces for adhesion, these discs streamline the finishing process.

Quick Change Discs have undoubtedly transformed the landscape of surface finishing by offering a seamless and efficient means of achieving desired surface qualities across various materials. With their rapid changeover capability, versatility, durability, and compatibility with different tools, these discs have become indispensable tools in industries requiring precision and efficiency in surface finishing.

As technology advances and materials evolve, the continual innovation in abrasive technology ensures that quickly change discs will continue to adapt and meet the evolving demands of various industries, providing efficient and effective solutions for surface finishing tasks.