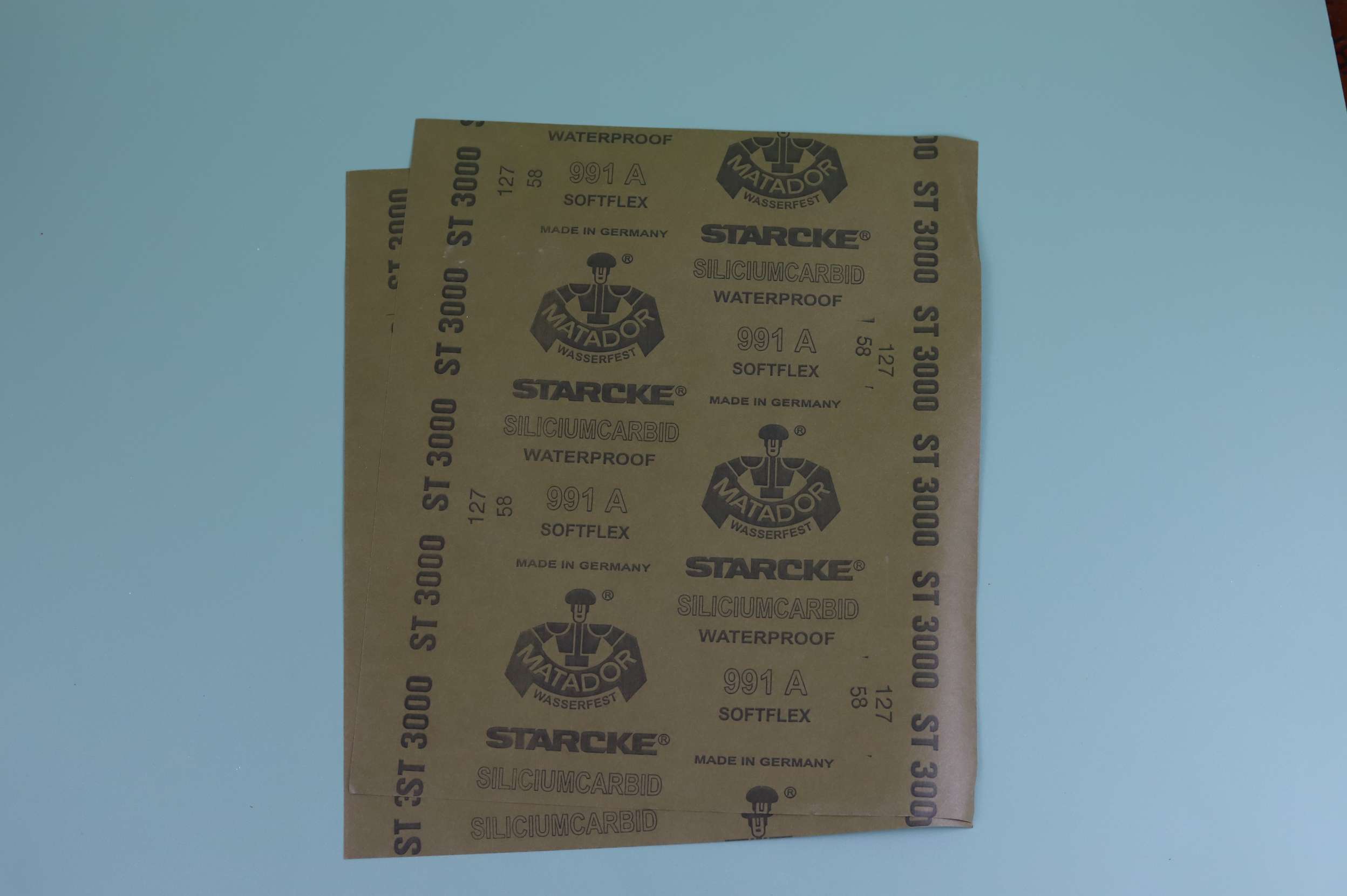

Products Description

- Grit Range: P36-P2000

- Attachment Type: PSA, Velcro, Plain

- Flexible premium C-weight paper disc excellent for general power sanding through work project

- Open coat structure prevents loading and increase life

- Even distributed Aluminum Oxide grain designed for heavy duty removal, fast cut, longer life

- Available in sponge roll (4.5” x 27yds)

HAZARDS IDENTIFICATION

a. The hazard identification is based on a formalistic procedure as the hazard statements of the ingredients.

b. The hazard statements of the ingredients are summarizies under section 3.

c. A greater hazard is the exposure to the dust/fumes from the material or coatings.

d. Most of the dust generated during grinding must be evaluated.

FIRST AID MEASURES

a. Eye Contact

Do not let the victim rub his eyes.

Gently rinse the affected eyes with clean water for at least 15 minutes.

Arrange for transport to the nearest medical facility for examination and treatment by a physician as soon as possible.

b. Skin Contact

Do not absorbed through skin. (may cause abrasions)

Obtain first aid or medical assistance, if needed.

c. Inhalation

Remove to fresh air.

Apply artificial respiration as needed.

Obtain first aid or medical assistance.

d. Ingestion

Obtain first aid or medical assistance, if needed.

FIRE FIGHTING MEASURES

a. Extinguishing media

Dry chemical powder, carbon dioxide, water should be used fires.

Use extinguishing medias appropriate to the source of the fire.

b. Special fire fighting procedures

Backing & resin binder will burn or decompose, use respiratory protection

STABILITY AND REACTIVITY

a. This material is stable.

b. Hazardous decomposition and polymerization will not occur.

c. Decomposition products : In use, dust and decomposing resin system fumes are generated.

In most cases, the material removed from the work piece will be significantly

greater than the coated abrasive product components.

As an aluminum oxide sanding discs manufacturer, Xinhongrui Abrasives has many years of production experience, welcome to consult us.

Aluminum oxide sanding discs are abrasive discs used for sanding and grinding surfaces, typically made of aluminum oxide material which is a tough and durable abrasive. They are commonly used for woodworking, metalworking, and automotive applications. The discs come in different grits, from coarse to fine, for various sanding and polishing applications, and can be attached to sanders or grinders using a hook and loop or adhesive backing.

Applications of aluminum oxide sanding discs

Aluminum oxide sanding discs are widely used for various applications such as:

- Wood sanding and finishing: Used for sanding and smoothing of wooden surfaces, edges, and curves.

- Metal Sanding: Used for removing rust, paint, or oxidation from metal surfaces, creating a smooth and even surface.

- Plastic Sanding: Used for shaping and smoothing of plastic surfaces, especially in the automotive and aerospace industries.

- Paint and Rust Removal: Used for removing paint or rust from various surfaces including metal, wood, and plastic.

- Glass Sanding: Used for sanding and polishing of glass surfaces, particularly in automotive and aerospace industries.

- Surface Preparation: Used for preparing surfaces before painting, varnishing, or other coating processes.

- These sanding discs are commonly used due to their durability, versatility, and cost-effectiveness.

Product detail & Main specification

Grain TypeAluminum Oxide

BackingCwt Paper (P60~800) Ewt Paper (P36, 40)

ColorYellow

CoatingOpen Coat

BondingResin Over Resin

Jumbo roll width1410mm