Products Description

- 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Ideal for the 3M two-step paint defect repair process for automotive finishes

- Well suited for use on mini random orbital sanders to produce a polish-ready finish

- Silicon carbide mineral in three very fine micron grades

Fine Sanding and Finish of Automotive Coatings

Available in three grades — A3, A5, and A7 — 3M Trizact Sanding Discs Finesse-it™ Film Disc Roll 466LA is the clearcoat spot repair disc used by automotive manufacturers worldwide. In convenient roll form, these discs are designed for quick access and attachment to rotary tools or orbital sanders.

While it breaks down faster than aluminum oxide, silicon carbide produces a brighter finish. It’s commonly used for defect repair on clear coats, paint, and plastics because it can effectively refine these surfaces without significantly gouging or damaging the workpiece.

Machine Sanding

- Level/remove the defect using the 3M™ Elite Series Mini Orbital Sander 28737 or the 3M™ Mini Random Orbital Nib Sander 20244 and a 3M Trizact Sanding Discs Finesse-it™ 466LA disc.

- Spray the disc with water to prevent the abrasive from loading during sanding.

- Sand the defect for 1 to 3 seconds, depending on its size.

- Wipe the area clean with a Scotch-Brite™ High Performance Cloth.

Function:

3M Trizact Abrasive Discs efficiently remove scratches, swirls, and other imperfections from a variety of surfaces. They are also ideal for finishing applications, as they leave an even and consistent finish. The micro-replicated structure of the disc surface ensures an even distribution of abrasive particles, thereby reducing the risk of surface damage and ensuring a high standard of surface finish.

3M™ Science: Precision Finishing by Design

3M trizact sanding discs Structured abrasives are precisely shaped, engineered composites that are evenly distributed and bonded to an abrasive backing. These extremely uniform abrasive structures can take the form of almost any three-dimensional geometric shape, including pyramids, hemispheres, and cubes, and are designed to enhance grinding performance. While conventionally coated abrasives often have erratically spaced minerals, Trizact™ abrasives are identical in height and orientation, wearing just as uniformly. As they do so, fresh, sharp minerals are exposed to produce a consistent cut and a predictable, fine finish. Altogether, this means fewer rejects and less rework due to out-of-spec results. Ongoing sharp cutting action minimizes the need to incorporate other abrasives in the sequence, thereby reducing processing steps and enhancing productivity.

Restore Polish, Repair Automotive Imperfections

The discs on 3M Trizact Sanding Discs Finesse-it™ Film Disc Roll 468LA are packaged in roll form, which makes dispensing the discs quick, easy, and convenient. Simply unwind the roll to reveal new discs. Moreover, the roll protects the discs’ PSA backings and abrasive face from dirt and debris until they’re ready for use. The PSA backing on these discs also helps speed your timeline, as no special tools or accessories are required for disc-to-tool attachment. 3M™ Trizact™ Finesse-it™ Film Disc Roll 468LA is engineered by incorporating silicon carbide mineral into a matrix of repeating microstructures; the film backing minimizes the chance for surface abnormalities. The pressure-sensitive adhesive on the back of the film adheres immediately to the tool back-up pad. The micro-structured silicon carbide mineral cuts sharply enough to quickly remove imperfections, but not so much so that you risk gouging or marring the surface.

Conventional abrasives are constructed from randomly spaced and irregular-shaped minerals

Combining the Power of 3M™ Trizact™ and 3M™ Finesse-it™ Abrasives

Derived from proprietary 3M Microreplication technology, 3M Trizact Sanding Disc Abrasives consist of precisely-shaped, three-dimensional structures distributed uniformly over the substrate. Unlike conventional abrasives, which are constructed from randomly spaced and irregular-shaped minerals, the uniform configuration of Trizact abrasives helps deliver consistent performance. 3M™ Finesse-it™ products are specially engineered abrasives, compounds, polishes, and buffing pads to be used on OEM and baked refinish paints to remove defects, sand scratches, or swirl marks on a variety of painted surfaces. Finesse-it™ products are an integral part of 3M’s recommended buffing system for repairing surface defects in clear coats, lacquered wood, solid surfaces, gelcoat, powder coat, industrial paint, and acrylic. When Trizact™ and Finesse-it™ are combined — you’re left with an abrasive that strikes the perfect balance for your automotive repair needs.

3M Trizact Sanding Discs Finesse-it Film Sand Roll 466LA uses 3M microreplication technology to form micron-sized silicon carbide particles into tiny ground mineral sand pyramids, which are then coated on a non-compressible polyester backing.

As the pyramids wear, new sharp sand is exposed for even cutting and the expected good surface finish. 3M Trizact Sanding Discs Finesse film abrasive roll can provide three grain sizes of A3, A5, and A7 for various topcoats and adapt to most surface effects and process requirements. Each roll consists of 500 individual film-based discs. Quickly access it and attach it to a rotary tool or eccentric sander. Unlike traditional abrasives, 3M Trizact Sanding Discs Finesse Film Roll 466LA is sharper and maintains a consistent cutting force for a desired finish and more uniform quality. 3M Trizact Sanding Discs Abrasive can last several times longer than traditional abrasive discs and can create precise surface effect control. For example, operators can reduce operating steps; process steps are fewer; and abrasive consumption is more economical. Trizact™ abrasives have a three-dimensional structure evenly distributed across the entire surface, ensuring consistent performance and eliminating disc-to-disc variation.

Product detail & Main specification

|

Abrasive Material |

Silicon Carbide |

|

Alternative Sale Availability |

This item is for industrial use only, and there are no VOC restrictions. |

|

Application |

Finishing |

|

Attachment Type |

PSA |

|

Backing Material |

Film |

|

Backing Thickness (Imperial) |

3 mil |

|

Brand |

Finesse-it™ |

|

Coat Type |

Closed Coat |

|

Color Family |

Gray, Green, Purple |

|

Equipment – Machines |

Nib Sanders, Random Orbital Sanders |

|

Hole Configuration |

125C, 143S, 200P, 300V, 75K |

|

Industries |

General Industrial |

|

Maximum Speed |

10000 rpm |

|

Max RPM |

10000, 12000 |

|

Micron Grade |

A3, A5, A7 |

|

Overall Diameter (Imperial) |

0.75 in, 1.25 in, 1.375 in, 2 in, 3 in |

|

Product Color |

Gray, Light Green, Purple |

|

Substrate |

Clear Coat, Paint, Plastic |

|

Wet or Dry |

Wet |

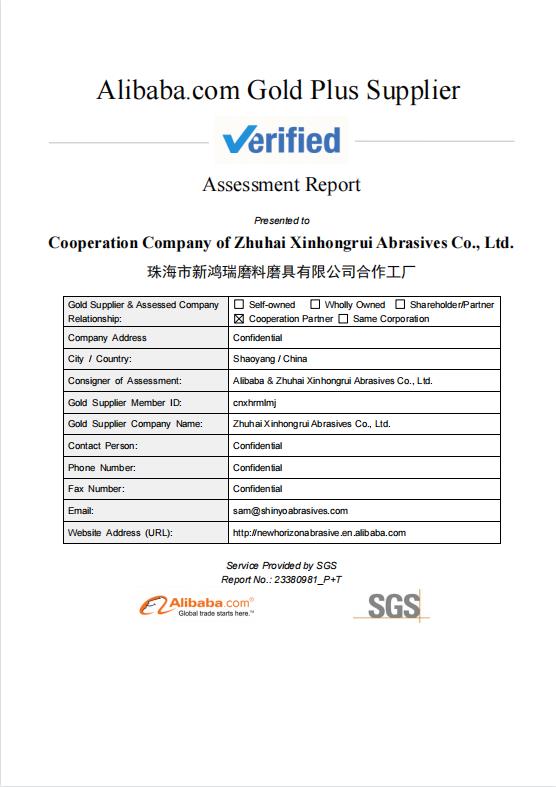

جertificate

Key Benefits of 3M Trizact Sanding Discs

-

Consistent Finish: One of the standout features of 3M Trizact™ Sanding Discs is their ability to deliver a consistent finish, regardless of the material being worked on. The uniform abrasive surface ensures that each sanding pass removes an equal amount of material, resulting in a smooth and uniform finish with minimal effort. This consistency is particularly valuable in applications where surface quality and appearance are critical, such as automotive painting and finishing.

-

Longevity: Unlike traditional abrasives that wear down quickly during use, 3M Trizact Sanding Discs are engineered for long-lasting performance. The durable abrasive pyramids maintain their sharpness and cutting power throughout the life of the disc, ensuring consistent performance and reducing the need for frequent disc changes. This longevity not only saves time and labor but also reduces abrasive consumption, resulting in cost savings for industrial users.

-

Reduced Heat Build-Up: Heat generation during sanding operations can lead to thermal damage to the workpiece and premature wear of the abrasive disc. 3M Trizact Sanding Discs are designed to minimize heat build-up thanks to their unique abrasive structure and advanced cooling properties. The microreplicated abrasive pyramids create channels for airflow, allowing heat to dissipate quickly and effectively. As a result, operators can achieve smoother finishes without the risk of overheating or burning the workpiece.

-

Versatility: 3M Trizact™ Sanding Discs are highly versatile and suitable for a wide range of applications and materials. Whether sanding metal, wood, plastics, or composites, these discs deliver consistent results with precision and efficiency. Their versatility makes them ideal for use in various industries, including automotive, aerospace, marine, woodworking, and metal fabrication.

-

Reduced Rework: The exceptional performance and consistency of 3M Trizact Sanding Discs contribute to a significant reduction in rework and touch-up tasks. By delivering uniform finishes with minimal surface imperfections, these discs help minimize the need for additional sanding and polishing steps, saving time and labor costs. This improved efficiency not only enhances productivity but also ensures greater overall throughput in industrial processes.

-

Dust Extraction Compatibility: Many variants of 3M Trizact™ Sanding Discs are designed for compatibility with dust extraction systems, further enhancing workplace safety and cleanliness. By effectively capturing and removing dust and debris generated during sanding operations, these discs help maintain a clean and healthy work environment while reducing the risk of respiratory hazards and minimizing clean-up efforts.

Applications of 3M Trizact Sanding Discs

3M Trizact Sanding Discs find applications across a diverse range of industries and tasks, including but not limited to:

- Automotive refinishing: Preparing surfaces for painting, removing paint defects, and refining clear coats.

- Metal fabrication: Deburring, weld blending, surface preparation, and finishing of metal components.

- Woodworking: Smoothing surfaces, sanding between coats, and preparing wood for staining or painting.

- Composite materials: Sanding and finishing composite materials used in aerospace, marine, and automotive applications.

- Precision machining: Surface finishing of precision components and parts with tight tolerances.