Introduction

In the world of woodworking and metalworking, achieving a flawless finish is both an art and a science. One of the most critical tools in this pursuit is the sanding disc, and among the myriad options available, the 3M 982C sanding discs stand out for their exceptional performance and durability. This article explores how these sanding discs make a significant difference in various applications, from the quality of the finish to efficiency and user experience.

The Importance of Sanding

Before delving into the specifics of the 3M 982C sanding discs, it’s essential to understand why sanding is such a critical process. Sanding smoothens surfaces, removes imperfections, and prepares materials for subsequent treatments like painting or staining. In both woodworking and metalworking, the quality of the sanding process directly impacts the final product’s aesthetic and functional qualities. Thus, choosing the right sanding tools is crucial.

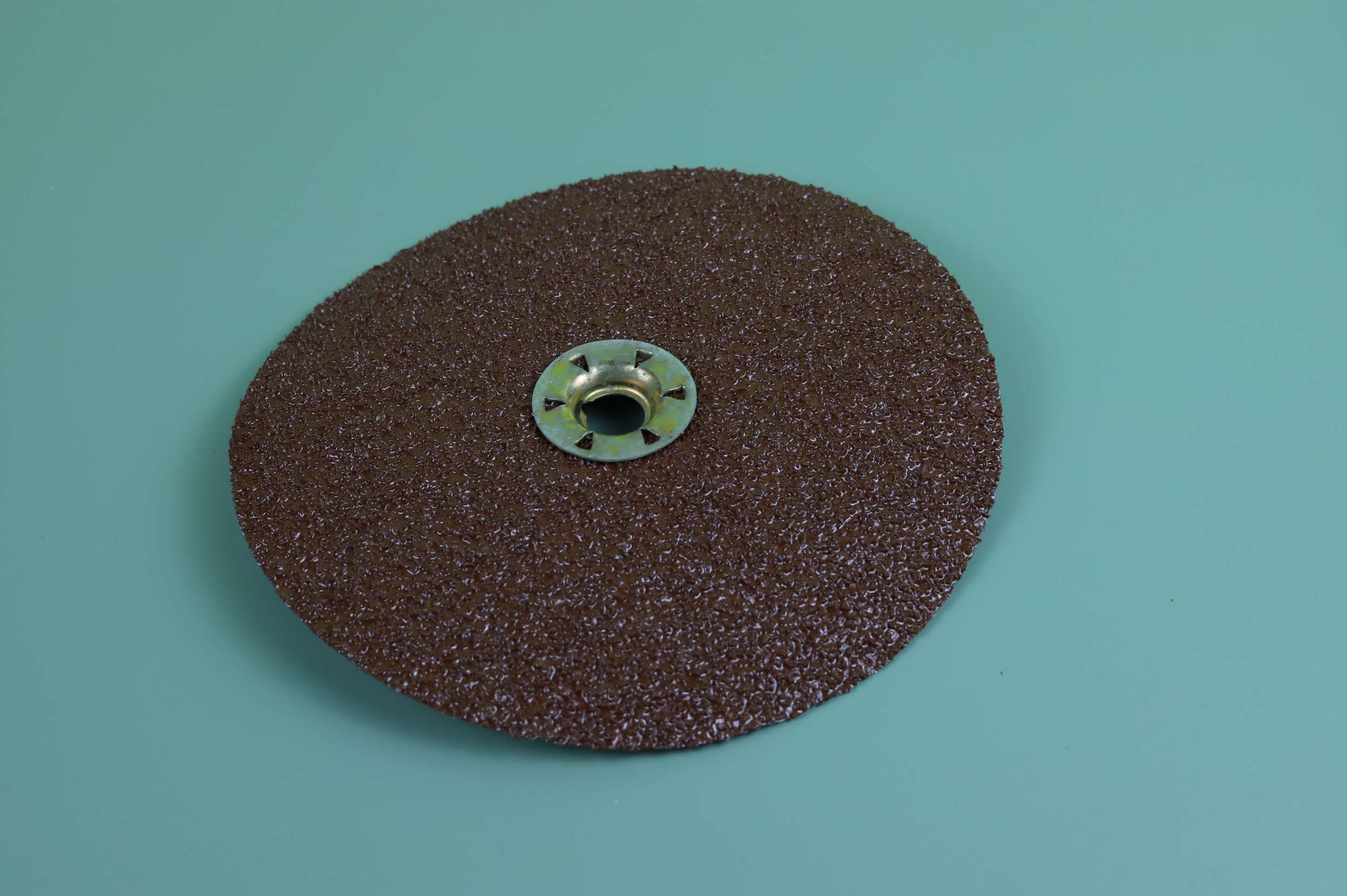

The 3M 982C Sanding Discs: An Overview

The 3M 982C sanding discs are designed with advanced technology to offer superior performance. These discs feature a precision-shaped grain that continually fractures into sharp points and edges, ensuring consistent cutting action. This technology not only enhances the cutting efficiency but also extends the disc’s life, making it a cost-effective choice for professionals.

Performance and Efficiency

One of the standout features of the 3M 982C sanding discs is their performance efficiency. The precision-shaped grain technology allows these discs to cut faster and more aggressively than traditional sanding discs. This efficiency translates into significant time savings, especially in large-scale projects where surface preparation can be a time-consuming process.

In woodworking, for example, these discs can quickly remove rough patches and smooth out the grain, allowing woodworkers to move on to finer sanding and finishing stages more quickly. In metalworking, the 3M 982C discs can efficiently handle tough materials like stainless steel, removing welds and preparing surfaces for painting or coating with minimal effort.

Durability and Longevity

Another critical advantage of the 3M 982C sanding discs is their durability. Traditional sanding discs tend to wear out quickly, especially when used on hard materials. However, the precision-shaped grain in the 3M 982C discs ensures that they maintain their cutting ability for longer periods. This longevity reduces the frequency of disc changes, saving both time and money.

The discs also feature a strong backing that resists tearing and edge wear, further enhancing their durability. This robustness makes them suitable for heavy-duty applications, providing consistent performance even under demanding conditions.

Versatility in Applications

The versatility of the 3M 982C sanding discs is another reason they are highly valued by professionals. These discs are effective on a wide range of materials, including wood, metal, and composites. This versatility means that a single type of disc can be used across different projects, simplifying inventory management and reducing the need for multiple types of sanding discs.

In addition to their multi-material capability, the discs come in various grits, allowing users to choose the appropriate coarseness for their specific needs. From aggressive material removal to fine finishing, the 3M 982C sanding discs offer a comprehensive solution for all sanding stages.

Enhancing Work Quality

Quality is a paramount concern in any sanding project, and the 3M 982C sanding discs excel in this area. The precision-shaped grain ensures a uniform scratch pattern, which is crucial for achieving a high-quality finish. Uneven scratch patterns can lead to visible imperfections in the final product, but with the consistent performance of these discs, such issues are minimized.

Moreover, the discs’ ability to cut quickly and efficiently means that less heat is generated during the sanding process. Excessive heat can damage the material being worked on and degrade the sanding disc itself. The cooler operation of the 3M 982C discs preserves both the tool and the workpiece, resulting in a better overall finish.

Ergonomics and User Experience

Beyond performance and quality, the user experience is an important factor when evaluating sanding discs. The 3M 982C discs are designed with user comfort in mind. Their efficient cutting action means that less pressure is required to achieve the desired results, reducing user fatigue. This ergonomic advantage is particularly beneficial in extended sanding sessions, where fatigue can significantly impact productivity and quality.

Additionally, the discs’ long-lasting performance means fewer interruptions to replace worn-out discs, allowing users to maintain their workflow and focus on the task at hand.

Environmental and Safety Considerations

In today’s industrial landscape, environmental and safety considerations are becoming increasingly important. The 3M 982C sanding discs contribute positively in this regard. Their durability means less frequent replacements, resulting in reduced waste. Moreover, the precision-shaped grain technology generates less dust compared to traditional sanding discs, improving air quality in the workspace and reducing the need for extensive dust collection measures.

Safety is another critical aspect. The robust construction of the 3M 982C discs minimizes the risk of disc failure, which can lead to accidents. By maintaining their integrity even under heavy use, these discs help ensure a safer working environment.

Case Studies and Real-world Applications

To illustrate the impact of the 3M 982C sanding discs, let’s look at a few real-world applications. In a large woodworking shop, the adoption of these discs led to a noticeable improvement in efficiency and product quality. Workers reported that the discs cut through hardwoods effortlessly, leaving smooth surfaces that required minimal additional sanding. The extended life of the discs also meant that the shop reduced its overall sanding disc expenditure.

In a metal fabrication setting, the 3M 982C discs were used to prepare stainless steel surfaces for painting. The discs’ aggressive cutting action quickly removed welds and surface imperfections, while their durability allowed them to withstand the demands of heavy use. The result was a smoother, more uniform surface that provided an excellent base for paint adhesion.

Comparing 3M 982C with Competitors

While the 3M 982C sanding discs offer numerous advantages, it’s useful to compare them with other products on the market to understand their unique value proposition. Traditional aluminum oxide sanding discs, for instance, tend to wear out faster and require more frequent replacements. They also generate more heat, which can affect both the disc and the workpiece.

Ceramic sanding discs, another competitor, offer good performance but often at a higher cost. The 3M 982C discs strike a balance between cost and performance, providing excellent cutting efficiency and longevity without the premium price tag associated with some high-end ceramic discs.

Tips for Using 3M 982C Sanding Discs

To get the most out of the 3M 982C sanding discs, consider the following tips:

- Choose the Right Grit: Match the grit of the sanding disc to the stage of your project. Coarser grits (e.g., 36-60) are ideal for heavy material removal, while finer grits (e.g., 80-120) are better for finishing.

- Maintain Proper Pressure: Allow the disc to do the work. Excessive pressure can lead to premature wear and uneven sanding.

- Use Appropriate Speeds: Adjust the speed of your sander to match the disc and material. Higher speeds can increase cutting efficiency but may also generate more heat.

- Inspect Discs Regularly: Check the discs for wear and damage before each use to ensure optimal performance and safety.

- Keep Workpieces Clean: Remove dust and debris from the workpiece regularly to prevent clogging and ensure a smooth sanding action.

Conclusion

The 3M 982C sanding discs are a standout choice for both woodworking and metalworking applications. Their precision-shaped grain technology, durability, and versatility make them an excellent investment for professionals seeking high-quality finishes and efficient performance. By choosing these sanding discs, users can achieve superior results, save time, and reduce overall costs. Whether you’re a seasoned craftsman or a hobbyist, the 3M 982C sanding discs offer the reliability and performance needed to take your projects to the next level.

Related Products