In the world of surface finishing and polishing, precision and efficiency are paramount. Over the years, the automotive, manufacturing, and metalworking industries have sought innovative solutions to achieve superior results. In this quest for excellence, it has emerged as a game-changer, offering a cutting-edge solution for achieving exceptional surface finishes. In this article, we explore the wonders of 3M Trizact 3000 and its impact on various industries.

Understanding 3M Trizact 3000:

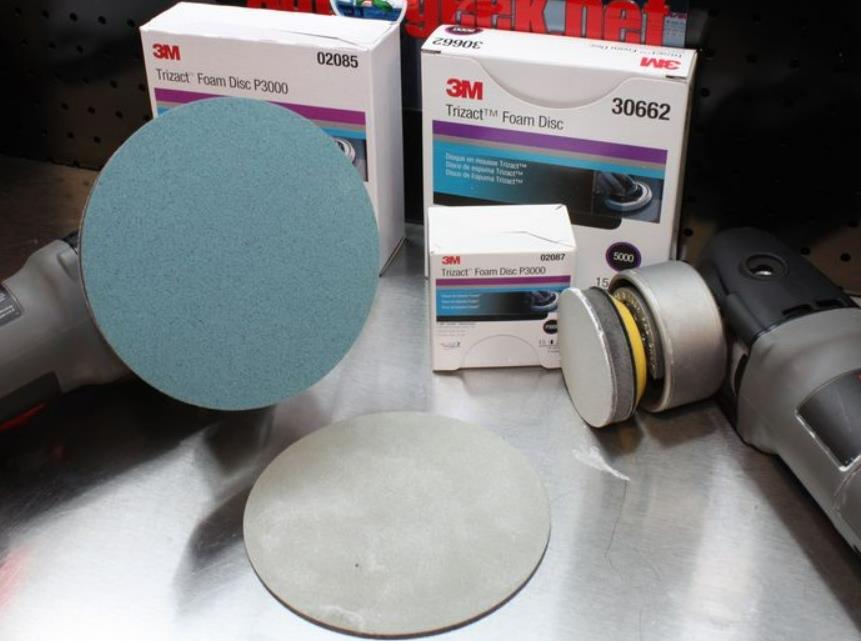

3M Trizact is a proprietary technology developed by the renowned 3M Company, specializing in high-performance abrasives. Trizact abrasives are known for their unique microreplication technology, which creates precisely patterned structures of micro-sized abrasive grains. The result is an abrasive material that delivers consistent and controlled cutting action.

Specifically, it refers to a particular specification within the Trizact product line. The number “3000” denotes the grit size of the abrasive particles. In this case, it represents a fine grade of abrasive with 3000 grit, making it suitable for fine sanding and polishing applications.

Advantages of 3M Trizact 3000:

- Uniform Surface Polishing: 3M Trizact 3000 utilizes micro-sized abrasive particles and special microreplication technology to ensure even wear during the sanding process. As the worn-out particles are continuously replaced with fresh cutting edges, the result is a consistent and uniform surface polishing, avoiding uneven defects and scratches.

- Efficient Material Removal: Despite its fine grit size, it efficiently removes material during the sanding and polishing process. This characteristic enables operators to achieve the desired surface finish quickly, reducing labor and time costs.

- Long-lasting Performance: Trizact abrasives are designed to maintain their cutting efficiency over extended periods of use. This longevity translates to reduced downtime and increased productivity for industries relying on surface finishing and polishing operations.

- Wide Applicability: It can be used on various materials, including metals, plastics, and automotive paints. Its adaptability and consistent performance make it an ideal choice for a wide range of applications.

- Precise Polishing Effects: Thanks to the microreplication technology and high-quality abrasive particles of the product, it delivers precise polishing effects, reducing material waste while improving work efficiency.

- Enhanced Appearance and Quality: 3M Trizact 3000 is widely used in automotive paint refinishing and metalworking, achieving fine surface polishing that enhances the appearance and quality of products.

- Reduced Environmental Impact: Utilizing the efficient product for surface finishing and polishing can reduce the need for chemical cleaners and excessive material removal, thereby lowering environmental pollution and waste generation.

In conclusion, the advantages of it have made it a highly favored abrasive material in various industries for surface finishing and polishing applications. Its efficiency, precision, and longevity serve as powerful tools to enhance productivity, improve product quality, and drive sustainable development.

Applications of 3M Trizact 3000:

- Automotive Surface Restoration: In the automotive repair and paint refinishing industry, it is extensively used to remove minor scratches, oxidation, and paint defects. Its fine sanding capabilities achieve high-quality surface restoration, providing a smooth, mirror-like finish to automotive paint.

- Metal Polishing: In metalworking and manufacturing, it is employed for polishing and sanding metal surfaces. It effectively removes dents, scratches, and surface roughness, resulting in smooth, precise surface quality.

- Plastic Surface Treatment: In the plastic processing and manufacturing sector, it is used for polishing and refining plastic surfaces. It helps eliminate scratches and imperfections on plastic surfaces, enhancing product appearance and quality.

- Wood Polishing: In the woodworking industry, it is used for polishing and sanding wood surfaces. It assists in achieving smooth, level surfaces for wood products, reducing swirl marks and imperfections.

- Craftsmanship: In the field of craftsmanship and decoration, it is used for polishing and fine-tuning the surface of handicrafts, creating exquisite finishes.

- Glass Polishing: In specific applications, it can also be used for polishing and refining glass surfaces, providing transparent, smooth results.

In summary, 3M Trizact 3000 is a versatile abrasive material suitable for various surface treatment and restoration applications. Its efficient grinding capabilities and refined polishing effects make it widely applicable in industries such as automotive, manufacturing, woodworking, and craftsmanship, offering high-quality surface treatment solutions to these sectors.

Usage of 3M Trizact 3000:

Steps:

- Wet the Abrasive: Soak the product abrasive in clean water for a few minutes to ensure it is thoroughly wet. Wetting the abrasive reduces friction and heat during the sanding process and helps clear away debris and material residue.

- Choose the Right Tool: Select the appropriate tool based on the specific application, such as handheld sanding blocks, power sanders, or other grinding equipment.

- Start Sanding: Attach the wet 3M Trizact 3000 abrasive to the chosen tool. Begin gently moving it over the surface to be sanded or polished. For sanding operations, gradually increase pressure, but avoid excessive force to prevent surface damage.

- Maintain Even Movements: During sanding, maintain consistent movements and pressure. You can use cross-strokes or sand in one direction, ensuring the entire surface receives uniform treatment.

- Monitor Sanding Progress: Keep an eye on the sanding progress. Depending on requirements, gradually switch to different grit sizes of Trizact abrasive, starting with coarser grits for initial sanding and transitioning to the product for finer sanding and polishing.

- Clean Regularly: Ensure timely cleaning of the abrasive surface, removing sanding debris and material residue. Keeping the abrasive surface clean helps maintain its sanding efficiency and lifespan.

- Polishing and Finishing: After completing the sanding process, you can continue polishing with the product to achieve the desired surface smoothness and brightness. Finish by using a clean cloth or polishing pad for final touch-ups and wiping.

Precautions:

- Exercise caution to protect your hands and eyes during sanding and polishing to avoid injuries or flying debris.

- When using power sanding equipment, follow the manufacturer’s operating guidelines and safety requirements.

- Depending on the specific application, appropriate personal protective equipment, such as gloves and masks, may be required.

The above instructions are for general usage of 3M Trizact 3000. Before proceeding with actual operations, please refer to the usage instructions and recommendations provided on the product packaging to ensure proper usage and achieve the best results.